Part IV: Wood Fired Roasters

Our four-part blog series Beans, Burners, and the Heat in Between describes the various roasting methods that use different energy sources. Previous posts in this series include Part 1: Gas burners, Part II: Pre-Mix Gas Burners, and Part III: Electrical Heating. Last but not least, we’d now like to end our review with the oldest roasting technique that has been used for centuries – ancient yet still intriguing, this roasting technique continues to fascinate roast-masters and roasteries worldwide – Part IV: Wood Fired Roasters.

Heating, cooking, or roasting with wood fired roasters have been around since time immemorial. The reason for using wood fired roasters nowadays is not necessarily availability, though that can be an issue in some cases. It is rather the opportunity to develop a wider spectrum of flavors. Coffee-Tech’s Wood fired Roasters are multi-fuel apparatus. They can be used with almost any type of fuel that offers similar caloric values, as long as it is suitable for an edible product. Fuel options range from wood pellets and wood wine barrels to coffee processing waste.

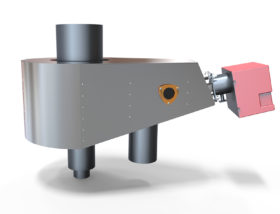

The key difference between Coffee-Tech’s wood fired machines and traditional coffee roasters, which have been around for over a century, is in the location of the burner’s combustion chamber as well as in its control features. In traditional roasters, the combustion chamber is located underneath the drum compartment. In modern machines, the combustion chamber is completely external. It releases heat through an insulated sleeve that originates in the combustion chamber, delivering heat to the drum. This allows for full and even heat distribution that offers swift, safe roasting. The difference between the two designs – the traditional versus the modern – is expressed in the mode of heat control. In traditional machines, the operator has just one chance to get it right. From start to finish, everything has to be precisely synchronized according to the quantity of coal or wood and the availability of primary and secondary air. Heat cannot be shut down retroactively.

Coffee-Tech’s advanced wood fired roaster has a pneumatic actuator that directs heat into the oven or alternately diverts it through the waste gate in order to cut heat off completely. Moreover, the operator determines modulation and thermal increase rates (as well as other parameters) using a digital frequency converter that controls the air suction by the drum’s blower through the drum. Heat rises when air suction increases, since air reaching the roasting chamber is forced to pass through burning wood. The combination of forced oxygen together with burning material is an unlimited source of heat. So much so, that the metal could glow and radiate, if you are not careful enough. By using just these two, it is possible to have full control over the profile’s entire thermal range so as at every pre-heat point.

On the practical side, it is possible to steadily maintain a state of pre-heat of 180 degrees over an unlimited period of time, regardless if you run out of burning material and have to add more while opening the combustion chamber door. This is actually hard to accomplish using gas. Going up and down within a certain range is unavoidable. Not with the wood fired roaster we have developed, though. That has always been the number one concern for those who dream of roasting coffee using wood.

Roasting using wood is made possible through radiation and convection. However, heat produced from burning wood is different in its composition from heat produced using metal, ceramics, gas flame, or electricity. When using wood as a heat source, the air that conveys heat contains a good deal of moisture and a host of other beneficial ingredients, from resin, aromas, and sugars to oils. The result of roasting with wood is spectacular. Because heat is transmitted through air, roasting is especially uniform and pretty swift. It does not suffer from issues known in other methods, such as scorching and tipping. Coffee beans maintain an amber-brown hue with a silky sheen and saturated coloration, evidence for an abundance of oils, sugars, and other essential coffee ingredients. Their presence is likely to make coffee appear darker, in terms of its roasting level, than it actually is. The dark, saturated coloration does not, however, result from the beans’ woody element – a phenomenon familiar from careless roasting. It results from an abundance of coffee properties. The same thing can be said, in fact, about every one of Coffee-Tech’s roasters, no matter the heating method used.

When selecting wood, one should take into account:

- moisture levels

- density and burning rate

- caloric value

- aromatic value, high/low presence of resin

- toxicity

Once wood type is given proper consideration, we can get down to practical experience. We can start by combining wood from trees such as oak, beech, or olive as a basis together with fruit trees such as apple, vine, walnut, pear, or citrus, for extra spice. Wood from pine or cedar is not recommended due to its high content of exceptionally aromatic resin. Using wood that has been treated against insects or disinfected – railroad ties, industrial waste, MDF, and the like – is strictly prohibited. Burning those is dangerous to operators, consumers, and the environment as a whole.

Another crucial difference: in traditional roasters, it was necessary to light up coal or wood in an external container to prevent soot from covering the drum on the inside. That tends to happen when wood catches fire. In modern wood-fired roasters, the combustion chamber is external. It features a separate heat surplus connection that transfers heat to the oven. Whenever necessary, heat can be rerouted into a chimney through an additional waste gate by turning off the burner switch. Smoke and byproducts, like soot, are then released without passing through the drum. This can be done even when the coffee roaster itself is off. This way there is no air suction into the drum, not even minimal.

Wood fired roaster offers a new dimension to roasting even when using a single woody origin. It will no longer be the same old flavor. New aromas will be incorporated originating from the wood. It is highly suitable for an espresso mix – certainly if it is rich in Robusta. Chaff generated from roasting can best be used as tinder when roasting with wood. In many ways, roasting using wood is “green.” At least burning wood is something human beings have always done. Perhaps this world of ours is better suited for burning wood than to other flammable materials. At least that is something one can believe in.

Ram A. Evgi