Part II: Pre-mix Gas Burners

In our previous post we described the first category of gas burners – self-aspirated burners. This time we will talk about the second category: pre-mix gas burners.

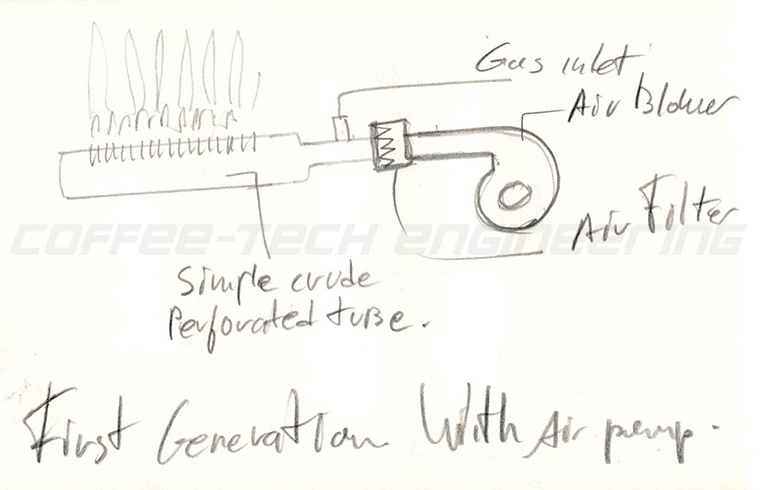

First-generation gas burners with air pump

This burner comes equipped with an air pump, and it is more ducted than pre mix.

This configuration came to life due to the known limitations of the self-aspiration technology and due to certain ambient conditions that can affect the efficiency and functioning of such burners.

Adding the air-pump is meant to compensate for lack of oxygen – in high altitude application, for instance.

In this crude initial configuration, the mixing feature and the projecting nozzle are quite simple: the design is poor and so is the efficiency.

The lack of efficiency is especially important since efficiency= pollution rate due to maximal burning of air/fuel properties.

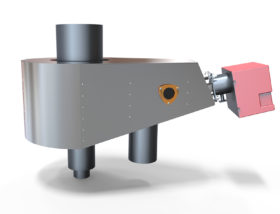

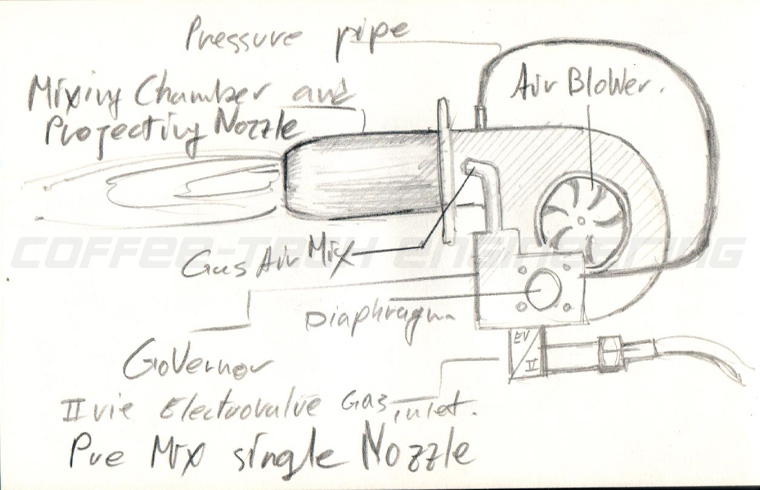

Pre-mix single nozzle burners

Pre-mix single nozzle burners are first level new-generation gas burners. Not only that, they can operate as multi-fuel burners. Such burners are equipped with a centrifugal blower able to calibrate air quantity. They also come equipped with a calibration valve that controls gas quantity. Controlling gas quantity ensures air and fuel mix in accurate amounts resulting in complete combustion that derives maximal caloric value.

Just like with anything else, there are many manufacturers of these burners. Design and quality naturally vary. In a good quality burner, a projecting/radiation nozzle or a heat-radiating metal screen will be installed to supplement the mixing chamber. Such efficient setup secures oxidation at the tip of the flame. This gets rid of toxins such as NOx and SOx generated by improper gas combustion. In its more basic form, this burner cannot be modulated using a single control knob. Modulation requires optimizing air quantity manually with almost every single change in desired gas quantity.

Pre-mix single nozzle burners combined with an efficient insulated combustion chamber provide consistent and correct thermal curves. This is particularly relevant when roasting for commercial purposes, compared to full-resolution burners where trial and error can never end, making commercial roasting inconsistence.

One good way to work with pre-mix single nozzle burners involves calibrating the caloric value produced by the burner to obtain a linear temperature increase from the moment coffee beans are poured in till the roasting process ends or the burner is shut down at the exothermic stage. The thermal increase rate is affected by few variables; heat distribution efficiency, heat conductivity, and heat absorption by the beans. The energy should be precisely regulate to match.

A second good method for working with such burners involves thermal increase in steps. Temperature can be increased in steps by turning off the flame several times for limited time intervals during the roasting process. In a closed environment, such as an advanced combustion chamber, turning off the flame for few seconds or even few minutes should not be a problem due to heat preservation of the chamber and the restriction of the secondary air inlet.

Many users of this method say they have no need for modulation or roasting software. Calibrating the thermal increase rate is enough. Assuming, of course, there are no problems with infrastructure.

As a rule of thumb, careful planning entails successful engineering and great thermodynamic performance, which are more important than gadgets and controllers. Such mechanisms are usually there to compensate for abnormal machine behavior. The goal of good machine design should be linear behavior and great performance coming from the roasting machine itself, without need for additional intervention. Take for example a familiar situation: cars. A well-designed car with good weight distribution and good components (like quality tires and smart suspension geometry) would not need as often to rely on anti-lock braking systems (ABS), electronic stability programs (ESP), or any other protection device, even when pushed to the limit.

Good design should make life easy, while delivering great results. Sophisticated display panels or controllers are nice to have, but not really necessary. Those can easily be added during the production phase or by clients themselves. However, poorly studied, arbitrary, or downright irresponsible design is there to stay. It will determine the quality of your end product indefinitely.

Unfortunately, many are concerned about the electronics and control with zero concern about the machine structure and thermodynamic character itself.

Pre-mix single nozzle, multi-stage, or fully modulated burners

Just like in the single/mono stage, in pre-mix single nozzle, multi-stage, or fully modulated burners caloric value can be changed and adjusted during roasting. With this type of technology, where the burner is located in a closed combustion chamber with optimal heat distribution, there is no need for full-resolution control. Two or three stages will provide perfect control for all commercial roasting purposes. Some roasting masters will nevertheless consider this insufficient. That is also fine: the technology is already here to match. As long as you promise to use it and are willing to pay for it, it can certainly integrate into your made-to-measure roaster. However, sometimes, high functionality can also be a source of confusion. Some clients are better off without a wide control range. Trust me, I have been supporting clients online for way more than twenty years since the early days of the Internet.

Having said that, 100% control is vital when the flame hits the drum directly. In this case, it is absolutely necessary to be able to go down to very low caloric values. On the opposite end, when the drum compartment is open and un-insulated, one has to take into account the cold surrounding air that interferes with the roasting process.

This type of burner can be found in certain commercial size machines, where two separate single-step burners are installed on a single roaster. The two single-step burners differ in size in order to generate double-phase heating that is reliable and easy to use and calibrate. Having two separate burners in the same roaster is not cheap. Yet, one combined double or multiple-stage burner can be harder to work with on a daily basis – sure it is harder to calibrate, yet you can order it, or a machine with even two of them, like the Ghibli line from 30 kg and up.

It is very important to mention; offering the simple path or a more simple technology is not a done out of patronizing attitude nor underestimation, we are simply calling it maturity.

We have the technology to offer a single stage, single burner machine that will produce such an excellent coffee that it will be very hard to duplicate with fully modulated burner, certainly if there are two of them installed on the machine. On the other hand, some have a real need for modulation or versatility due to the character of their own business, the selection has to be well thought and mature.

We, at any rate, do offer all these types, from single stage to few fully modulated in array.

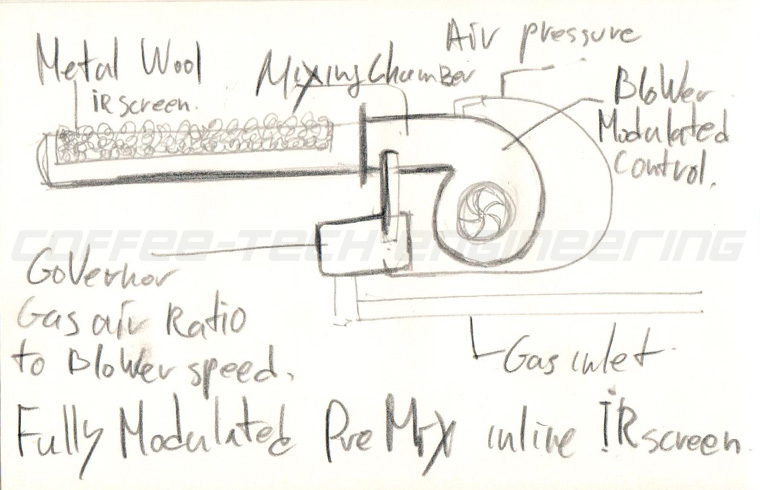

Pre-mix gas burners technology, low NOx, the latest generation.

What makes gas burner efficient, as far as it has to do with the burner itself, is the quality of the mixing between air/fuel, the quality of the projection, and, most important, the ability to burn completely the entire preliminary mixture,

The technical obstacle is capturing the mixture or parts from it from escaping the flame core, as it is in motion and constant flow.

Particles that manage to escape from burning are free now and will never be back to combustion, and are called polluting properties.

Therefore the design of the burner must be as most efficient as it can be.

In our latest generation burners we manage to reduce pollution and increase efficiency to the maximal rate known in the industry.

This type of burner, fully modulated burner, has wide projecting screening, It is fitted with an micro perforated SS distribution sleeve for initial distribution, and covered by a high-grade molybdenum woven alloy. The woven alloy is responsible for distributing the mixture and the heat evenly and effectively, ensuring complete combustion of all gas particles. It also generates high-frequency infrared radiation.

Woven alloy screen functions as a highly efficient oxidizer, as anything must go through it, and this glowing woven simply burns completely all particles.

This distribution patterns, well known in self-aspirating burners, together with pre-mixing technology and complete, full-resolution control, makes it one of the most advanced burners currently available on the market. It offers the most flexible and efficient profile so far.

Combining pre-mix technology with the old systems can perhaps improve things a little. However, air cannot be compressed without resistance. This does not work for candle burners, among other things, since the flame must be maintained. It is not worth the effort – there are already far more advanced technologies out there.

The infrared screen on that pre-mix burner is a unique Coffee-Tech innovation. To be honest, even without it, Coffee-Tech’s line of coffee roasters already features machines that are extremely precise in production values and offer highly impressive thermodynamic behavior. Our main motivation for developing such a burner was to produce a component that can meet no objections. Without getting into a longwinded account, it is enough to simply make it available and offer our honest opinion on why it is needed. As always, we hope for the opportunity to express our humble opinion, even to those who think they have no use for it.

Life has taught us that, more often than not, many choices colleagues make are emotionally driven. Coffee roasting is often a matter of spirited opinions and intuitions. Take, for instance, the passion sworn fans feel towards the FZ-94 Lab Roaster for its wide control options. At the same time, the automated Solar Shop Roaster, with its single control button, might be far more suitable for their actual business needs. This can also be said of exotic technology we offer with various burners and drums. Nevertheless, we can say with great satisfaction that our clients establish an influential, successful business thanks in part to such unique equipment.

It is true: our equipment was designed with certain restrictions in mind, intended for commercial roasting within the specialty coffee market. As a consumer, you would certainly expect the manufacturer to sort the grains from the chaff. In our business, this is done both literally and figuratively. Imagine a taxi driver getting the Rally version from Renault. How pleased are his passengers going to be? Or the cabbie, having to change tires every 500 km? The cabdriver’s mechanic is likely the one to get the better end of the stick. It is time to grow up and move on. Some of you are in it for the money, which is absolutely fine. Whatever your motivations and aspirations may be, give us a holler. We know a lot about racing cars and exotic features. We our notorious for manufacturing Formula One roasters just for the roasting fun of it.

The fact that a burner is working properly and producing heat does not mean all is good. There are lots of other things and specs to make a roasting machine a good one.

The challenge is how to transform the heat in a safe manner onto the coffee beans.

In electrical heating, the thermal range is precisely defined to allow for safe, sufficient levels of energy, no more nor less than necessary. (gas burners can be much more overpowered by their nature)

Electrical powered machines are usually designed for linear curve unless the electrical heaters use the bulb method that glow fairly fast, almost like a flame. But the negative point is their short lives and their fragility.

This takes us to our next subject and our next post: electrical heating. It is the cleaner source of heat, and ‘clean,’ as I hope we can agree, is much more than a luxury. Sometimes, it is also more than a question of choice, when gas is simply not an option. For those two reasons and more, electricity deserves more attention and further research.

(Ram A. Evgi)