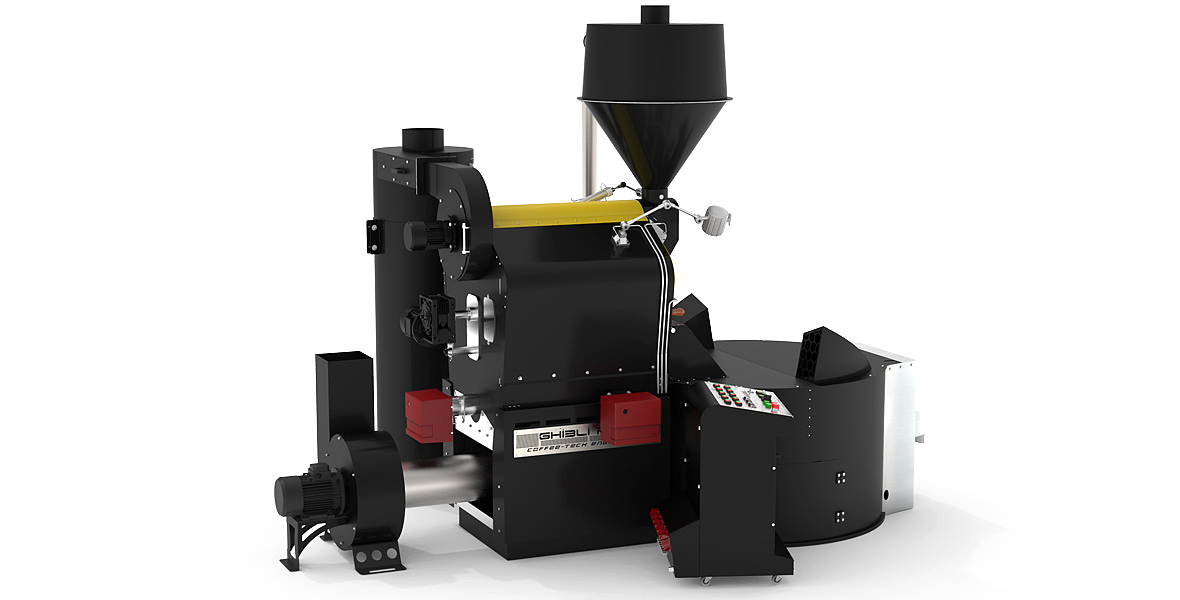

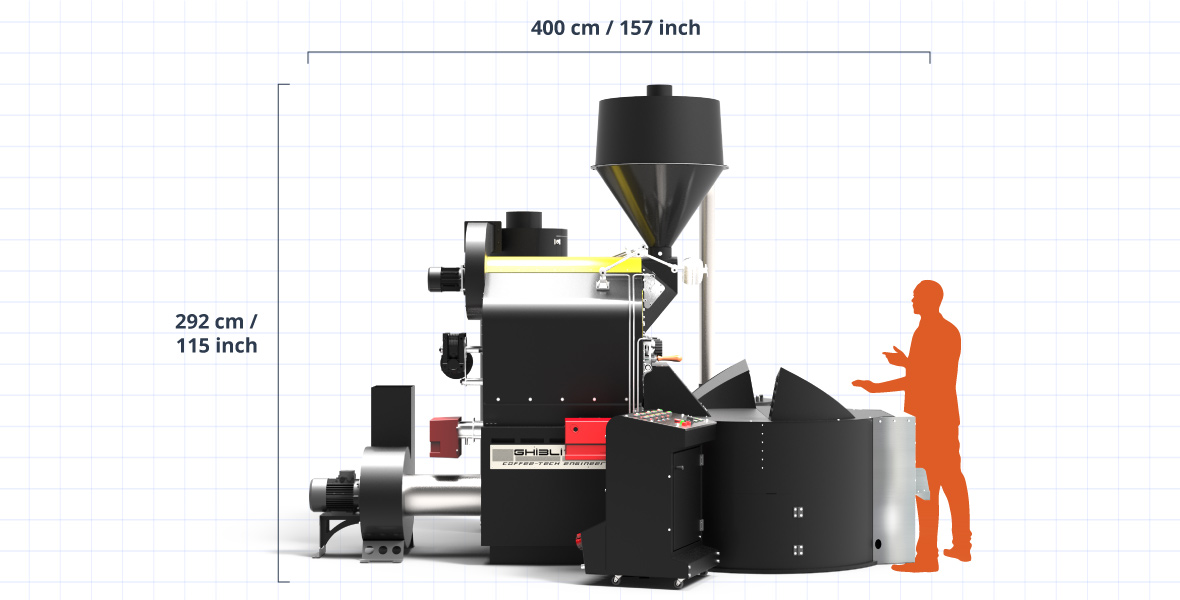

Roasting large amounts of coffee doesn’t mean you have to compromise on quality. Ghibli R60 our 60Kg. batch commercial roaster provides you robust, consistent and quality roasting device at hand. Coffee Tech Engineering paves you the way for producing top quality coffee and meeting the growing demand from your customers for quality, freshly roasted coffee.

Operation: Easy, Consistent and Repeatable

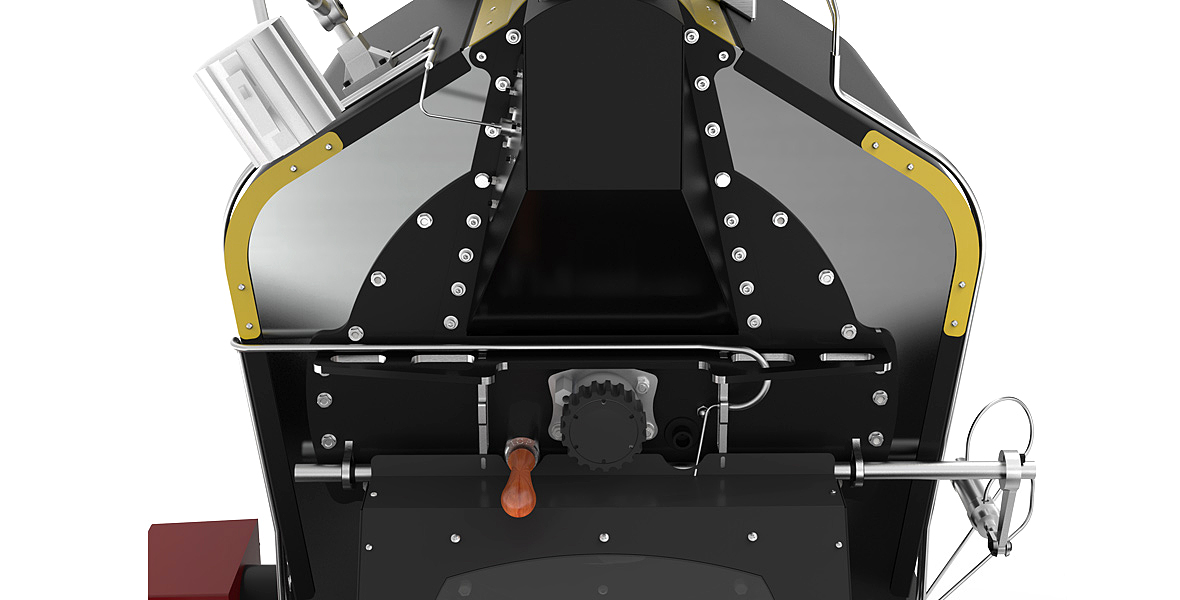

Roasting coffee in large quantities means you can’t afford to miss orders and lose batches due to inconsistent results. Ghibli R60 provides you an intuitive control system for easy operation throughout the entire roasting process. Temperature reading is always accurate and easy to read; several inspection lenses provide you first hand impression of roasted beans, flame and more. You may sample beans while roasting advances and accurately determine when to end it.

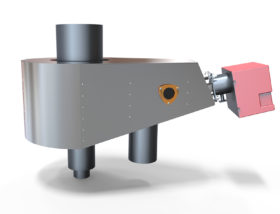

Energy: Efficient, Safe and Clean

Ghibli R60 presents advanced thermodynamic behavior throughout the entire roasting process. The entire Ghibli line is equipped with the most efficient gas turbo burner. It is a clean heating source, providing maximal efficiency in gas burning and minimal emission of Carbon Monoxide. It is safe, economical and stable, with many unique parameters to control and calibrate its output.

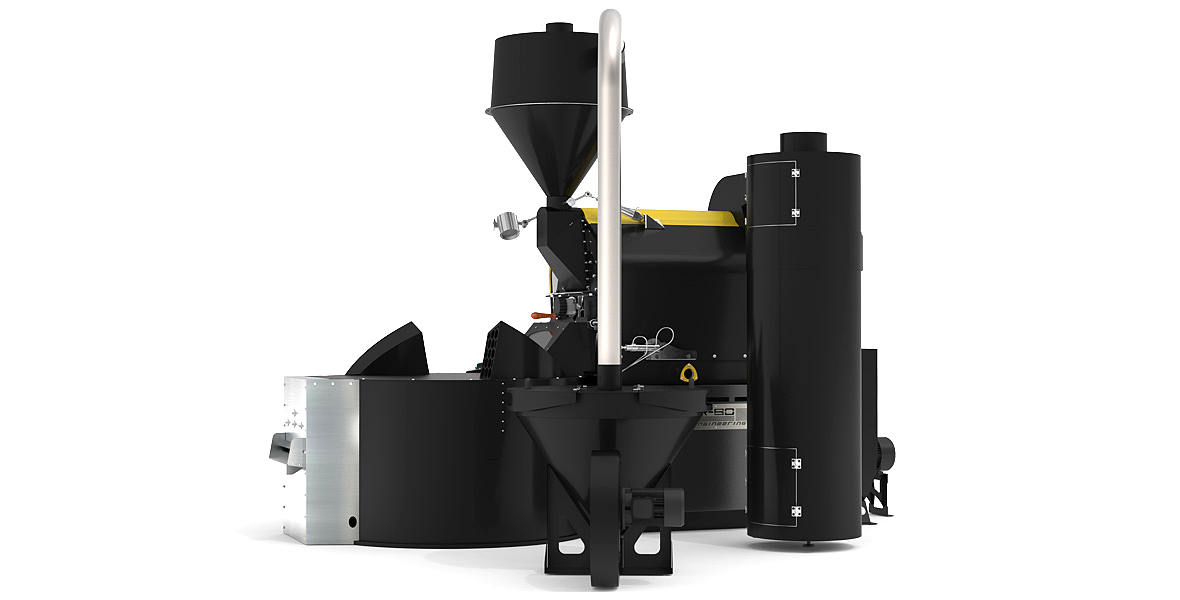

A Complete Production System

Ghibli R60 is the heart of our most compelling coffee production system. You control the entire production process from a single control panel. The Complete production system is comprised by the following components:

- Automated Loading System – integral part of the roaster

- Destoner (Optional)

- Ghibli R60 Roasting System – Roasting, cooling and chaff collection

- Afterburner – Smoke solution (optional)

Additional Features

Design and Manufacture – Ghibli R60 was designed and manufactured using the most advanced technology. Thanks to the careful planning and precision manufacture, we achieve life-long aligned drum and easy maintenance and service. Thermal Behavior – The ceramic combustion chamber assures the thermal stability and energy efficiency of the roaster. Cooling – Fast beans evacuation and rapid cooling will stop the roasting process immediately and allow you to safely start another batch. No quenching is needed. Safety Features – Fire extinguishing system is assembled inside roasting drum and chimney to minimize fire hazard involved with roasting.

Ghibli R60 Commercial Roaster Brochure EN.PDF

Ghibli R60 Commercial Roaster Brochure DE.PDF

Ghibli R60 Commercial Roaster Brochure ES.PDF

Ghibli R60 Commercial Roaster Brochure IT.PDF

Ghibli R60 Commercial Roaster Brochure RU.PDF