Part III: Electrical Heating

Electrical heating is the cleanest heating source available for roasting. This is just one of its many advantages. And just like with everything else, there are also some disadvantages, at least according to some roasters. One thing is certain: in some cases, gas is not an option. In these cases, developing electricity as a highly efficient heating source is an absolute necessity. Quality of design and production is key. This is no small matter, when electrical heating comes in so many forms: exposed high-temperature metallic coils mounted on an insulated ceramic base, insulated tubular units, or ceramic or glass units with especially high radiation capacity, and more.

Air pollution resulting from gas burners starts before actual roasting begins, at the very moment heat is switched on. With electricity, the problem simply does not exist, since electrical heaters obviously do not emit harmful fumes by themselves. Electricity allows for highly efficient heat distribution and radiation with reliable performance, as compared to gas. When using an automatic shop roaster or a lab roaster, these are all an absolute must: stability, uniformity, consistency, and regularity.

The claim that an electrical heating unit reacts slower than a flame when temperature is on the up or down gradient is only partly true. Given the right design, electricity does not only improve roasting quality but also makes it safer, exactly because of its moderate thermal response. Good design and proper calibration can adequately match the rate of temperature change in a given machine. This makes the machine easy and safe to use, in terms of getting the best results with a low or, in fact, any learning curve. Calibrating energy output in proportion to machine mass is the name of the game.

A flame is similar to air in its physical makeup. Therefore, it does not exhibit thermal continuity by itself. Turning down the flame immediately cuts off the source of heat and radiation. However, that does not mean heat shuts down at the same instant rate. Thermal mass has accumulated in the metal, especially in cast iron machines and stainless steel drums.

Circumstances that require intervention by shutting down the flame occur only on the learning curve of a roasting profile or in extreme cases. Most of the time, the correct way to go is to modulate the flame or set up a uniform linear gradient by regulating static burner levels. Therefore, there is no definitive advantage to gas over electricity as far as heat control is concerned. When considering well-designed roasting machines – they arguably require an adequate level of knowhow to come up with – most cannot be adapted to gas. A roasting machine must be designed from scratch for this specific purpose, if there is any chance of achieving a good result.

Needless to say, not all electrical heating methods give rise to high thermal continuity and mass. Those that use infrared radiation as their chief heating method cut off heat radiation immediately. Without radiation – the leading source of heat, generating the highest temperature – any significant heating activity is completely suspended.

A bare flame produces heat radiation instantly. Electrical heating units, on the other hand, experience a time lapse till they reach full (or pre-specified) radiation levels. Assuming all this is true, we should ask, but then, so what? Is the drum able to instantly transfer or the beans able to instantly absorb that generated level of heat? The answer to both questions is: definitely not when the flame draws near the beans, when the drum is already hot, and heat has nowhere else to dissipate.

With electricity as a heat source, reaction time to heat increase matches the beans’ capacity to absorb it. This is especially true, when we consider heat modulation during roasting. At this point, there is no energy loss, since the roaster is in full working mode, temperature-wise and otherwise. We are assuming, of course, that engineering is robust, meaning, calculated, rather than arbitrary.

Electrical roasting is considered highly uniform, clean, consistent, and safe compared to gas. Roasting using gas is like steering a boat in stormy waters, hence the shenanigans over full modulation. Once there is energy surplus, burn marks appear. Then comes intervention and immediate flame shutdown or reduction. Most gas roasters tend to use too much energy. They can also be hard to calibrate within the min/max range. Meanwhile, electrical roasters are highly accurate and consistent in their output (subject to developer specifications). So when it comes to electrical roasting, the process resembles walking on far more solid ground: it is always possible to predict behavior in the next phase and act accordingly. Certainly, there are a few examples of bad performance, here and there. Still, we are talking about the leading products in the field with the most advanced technology.

Tackling the issue of heat modulation, Coffee-Tech implemented drum speed control in all of its roasters, for example, the Silon ZR-7 Shop Roaster, the FZ-94 Lab Roaster, and the Ghibli Commercial Roasters line, with this exact goal in mind. This unique feature does not belong directly to heat spectrum manipulation, but it does have an immediate impact. One striking discovery that each one of our clients makes is the effect of drum speed on temperature reading points. There is no longer need to interrupt burner function. Speeding up the drum is all it takes for heat to be better absorbed by the beans.

As drum speed increases, bean temperature rises, while air temperature inside the drum decreases. A controller responsible for taking readings of air temperature inside the drum sends signals to the burner. Once a certain target temperature is reached, the burner shuts down. This creates a time lapse between turning off the burner and reaching the target point. It allows the beans to remain in a hot environment with safe, de-localized heat distribution. This also occurs when drum speed is low or fixed, in which case the beans are exposed to the drum’s hot metal surface for longer time intervals. The speed regulator is thus used as a modulation device, controlling bean heat absorption without interfering with burner function. Utilizing such an innovative roasting method, it is now possible to roast with constant, steady heat (whether resulting from electricity or a flame) and set up a radial profile, relying solely on drum speed.

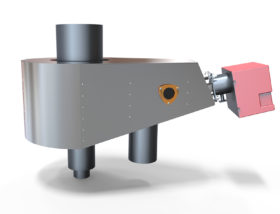

Those Coffee-Tech roasters equipped with electrical heating as a possible configuration or sole option are the Solar Shop Roaster and the FZ-94 Lab Roaster (we are also considering adding electrical heating to the Silon ZR-7 Shop Roaster at some point in the future). Considering the Solar Shop Roaster, from the moment heating is on up to the exothermic phase, each one of its three heating units operates in full radiation capacity. Heat is perfectly distributed at a angle relative to drum surface. The Solar Shop Roaster provides the perfect level of roasting, as if by magic.

To be honest, there is no magic when it comes to machines and engineering. What we are dealing with here are specialized roasters that stand for superb engineering subject to strict specs. Nothing is designed by chance. That is how it should be with every development and production process. Just like in any other field, products come from different places, but one quick look should reveal the level of investment in development prior to production. This does not depend on the choice of heat source, whether gas or electricity. And why not wood? Wood may be old school in source but not in design. Wood burner design can strive to be just as sophisticated, when the clever engineer is ready to take on the challenge. The next and final article in my four-part-blog on burners will be dedicated to wood, the old-new kid on the roasting block.

(Ram A. Evgi)