A conversation with Aron Gyuga of Herz Vanilla and Herz New York Coffee Roasters.

The Herz enterprise started in 2010 after Pal Gyuga, who had a business in foreign trade, wanted to pursue his passion for coffee. Knowing the distribution, marketing and sales side of the food industry, Pal had a good starting point for his coffee business. He also knew what good coffee tasted like and with time, effort and experimentation, Pal was confident he would be able to make a product he was proud of and people would want to consume. After Pal had successfully launched his coffee roasting endeavor, he also wanted to professionally embrace the taste and field of vanilla. The business grew its capacities to also operate Herz Vanilla (2019), a company that would become known for high quality vanilla beans, extracts, powders and pastes.

Recently we had an opportunity to speak with Aron Gyuga the son of Pal, a director for the company and ask him for some of the more helpful and interesting tips that he was willing to share with others who wanted to get into Coffee Roasting as a profession or way to make supplemental income. Aron, ever humble in their accomplishments was not hesitant to share some great tips on what to do and what to avoid in the field of coffee.

Q: How did they get into the coffee business?

A: Pal was always a big fan of coffee and pursued his interest. He had the idea of developing and manufacturing his own brand instead of distributing other companies products. Later the whole family started contributing and it grew.

Q: How many countries is Herz distributing in?

A: Hungary, Germany and the U.K.

Q: What tips do you have for startups in the coffee industry?

A: When developing a new brand, do not rush products to market. Quality should be the first focus if you are a brand who emphasizes quality. Take plenty of time in developing products, “It is hard to sell a product to a customer a second time if they did not like it the first time”. Even when a testing phase feels like it is taking too long, be patient.

Q: What is the biggest challenge at the coffee roastery itself? Specifically when it comes to roasting?

A: Familiarizing yourself to green coffees from different regions. Each origin of bean is completely different from others. You end up developing methods for roasting depending on where the bean came from.

Q: After you start working with a new type of raw coffee, how long does it take to understand what changes should be made to get the desired results?

A: After 3 or 4 different roasts we know how the coffee reacts and what needs to be done to the roasting profile to be happy with it. Coffee brokers and farms have recommended roasting curves for the different types of coffee. We start with this and make changes using our own knowledge and style to figure out the best method to roast.

Q: Is there a type of coffee that is more challenging than others?

A: The African coffees can absorb more heat than the others. I think Central American coffee types are more sensitive. But, I believe the longer you roast coffee the more experience and knowledge you have, eventually you adapt your roasting methods to the different types of coffee roasting requirements.

Q: What is the most recent trend or fad that has your interest in the coffee world?

A: Last year I was at our 3rd generation green coffee trader in Trieste and there was a rum barrel method used on the coffee while it was still green. After it was roasted, we drank it as an espresso and it was amazing. You could taste the rum even though the coffee was dried and roasted after it was soaked. There were so many aromas, since then it has become an obsession. I definitely want to pursue something like that. Even if it’s not rum, some kind of aging or fermented beans will be somewhere in the product line. It’s still in the thinking phase. In the long term we would want to test the different methods ourselves and develop something, I would not want to order the green coffees presoaked. It must be before the roasting stage though, no extracts or additives after the roast.

Q: What is currently driving the innovation and changes in the coffee market? What are you seeing as a producer?

A: Now the coffee market is really, really competitive. In the last 6 or 7 years there have been many micro roasteries enter the market that offer the exact same single origin coffees. You have to come up with something new and unique to distinguish yourself. It’s also good because all these roasteries are making the market stronger, consumers now have many options to find something they like.

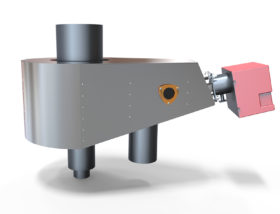

Q: What made you decide to roast with a Coffee-Tech Engineering roaster? How did you learn of Coffee-Tech Engineering?

A: My father did the research. We wanted to change the previous roaster we were using and get a new one. He found information for different roasters and chose the one he thought would be best for us.

Q: What were your fathers’ specific requirements for his new coffee roaster?

A: We wanted manual and automated roasting options. A well-developed roaster that was user friendly with a nice interface. Also, my father has an artistic mindset. He really likes the minimalistic design, small space requirement, it was important to have something that stood out. We really loved the design at first and then the engineering and function of the roaster was well developed and reputable. We can adjust the burner, airflow, the drum speed. Those are really important things, it’s really impressive.

Q: Is there anything else you would like to add about Herz Vanilla?

A: Yes, we are splitting the company from Herz Vanilla to Herz Vanilla and Herz New York Coffee Roasters. We wanted 2 separate distinguished entities for our vanilla products and our coffee products.

Herz not only stays current with consumer trends such as recyclable aluminum capsules for their coffee as an alternative product delivery, they even diversified their product field to successfully find a place in both. Herz Vanilla and Herz New York Coffee Roasters required dedication and patience that is only found accompanying a strong passion. Product integrity, consistency, distribution, marketing, spoils, these are all difficulties that have to be solved and paid attention to at a continuous rate in the coffee industry. Maintaining what you have while building new and expanding your product line alongside your audience is a continuous pursuit and will require both, effort and knowledge. Making sure the equipment you have involving your production is very important. If customer demands shift, it’s best to have equipment that can provide whatever new ability it is you are requiring.

Thank you Aron Gyuga for your assistance

Chris Nance / Moshav Mazliach / May 5, 2022