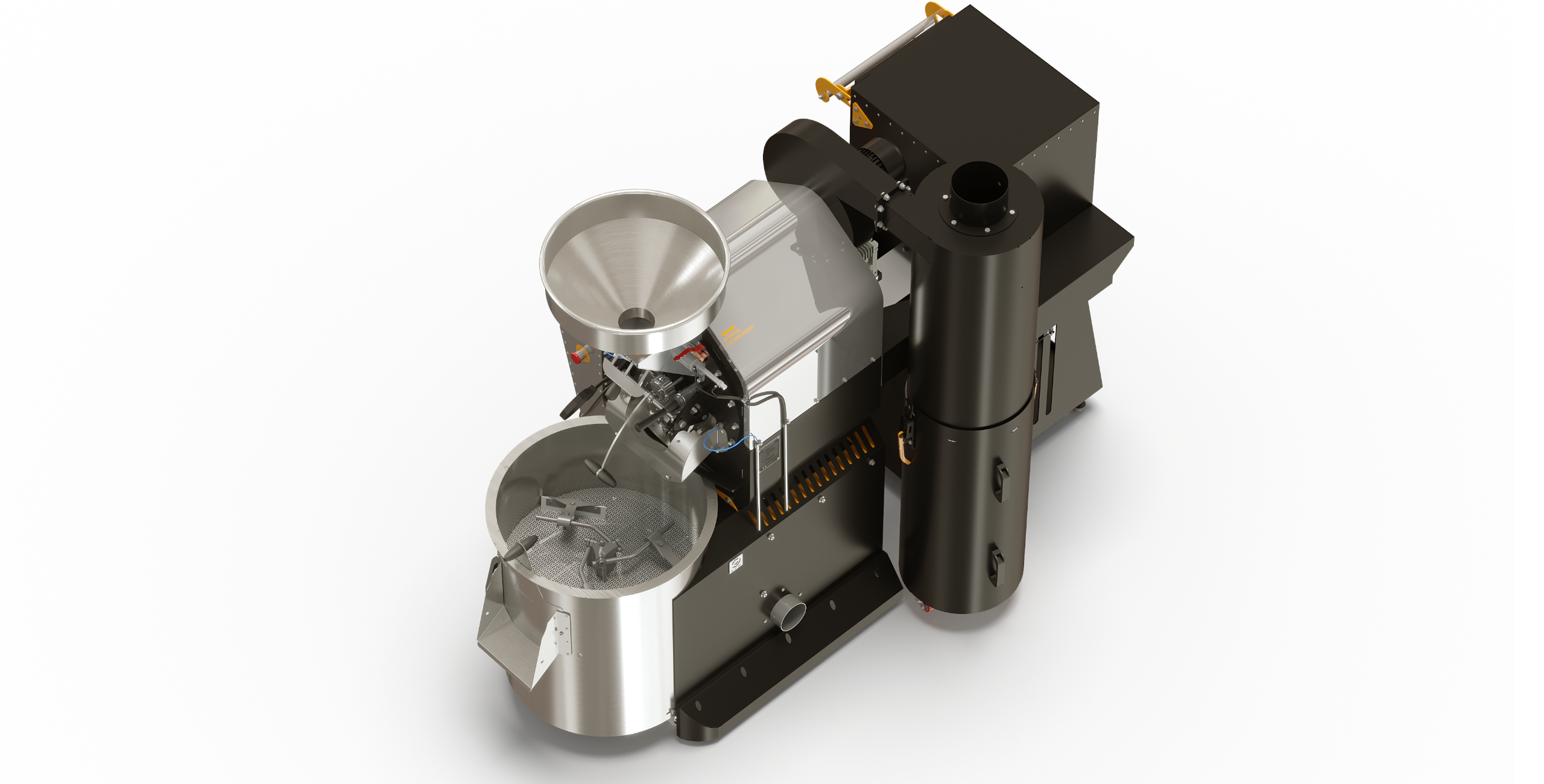

Where technology meets tradition. The Ghibli Firewood commercial roaster utilizes wood combustion for roasting. Roasting occurs by means of convective hot air that flows across the roasting drum, transferring heat and the aroma of the wood to the beans. With this method of roasting, the end result is influenced by the type of wood being used, from natural coals to aromatic chopped fruit-wood or other aromatic types such as oak.

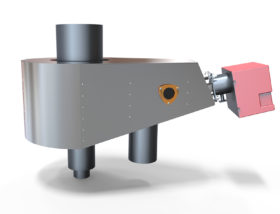

The Ghibli Firewood is one of the most advanced roasters in the industry. The roasting process can be conducted manually by digital temperature control or automatically by the accompanying software. Heat is directed to the drum housing for heating through a pneumatic selector box that features a waste gate connected to the chimney, which can block heat quickly. The Ghibli Firewood operation is extremely clean and simple, with a highly efficient firing group that consumes a small amount of wood per batch. For example, one batch will only use roughly two pieces of wood, depending on its size.

Using the Ghibli Firewood to roast is much more than just another marketing highlight – it is joyful and, in a way, easier and more intuitive than roasting with gas, as only an organic heating source is being used. This also adds a whole world of flavors to your precious coffee. Wood aroma is the only legitimate addition to the aromatic spectrum of your coffee. Nevertheless, roasting with a neutral flavor is easy – simply use natural coals. Roasting times with the Ghibli Firewood are relatively short as a batch of 15kg can be roasted in 11 to 16 minutes. Roasting with the Ghibli Firewood requires a pressurized air source for the selection box actuator.

Ghibli Firewood Commercial Roaster Brochure EN.PDF

Ghibli Firewood Commercial Roaster Brochure DE.PDF

Ghibli Firewood Commercial Roaster Brochure ES.PDF

Ghibli Firewood Commercial Roaster Brochure IT.PDF

Ghibli Firewood Commercial Roaster Brochure RU.PDF

Ghibli Firewood Commercial Roaster Brochure FR.PDF

Ghibli Firewood Commercial Roaster Dimensions.PDF