Coffee and Cocoa have been staples in the human diet for a very long time. Since 1500 BCE, cocoa roasting has been embraced for the pleasure of all who consume it. Almost three thousand years later, early in the 15th century, the knowledge and practice of roasting coffee beans spread quickly across Africa, Europe, and the Middle East. The appeal of these stimulants may be due to our attraction to caffeine and the euphoria or energy it provides. For the better part of six centuries, both of these beans have played a large part in our history. Becoming a daily ritual for a large portion of the planet, coffee and cocoa have experienced nonstop growth and demand since their domestication.

The initial roaster was a concave metal pan with a long integrated handle, placed over a charcoal or flame pit in the desert soil. The stirring stick was a required tool do to the importance of keeping the beans moving during the roasting process, preventing heat exposure in one spot for too long. Around 1650 AD the first “drum” roaster, equipped with a manual crank and made of metal, first appeared in Cairo. Quickly becoming a common tool with variations appearing in southern Europe soon after. Newer versions would evolve to render better agitation and heat distribution with a spherical shaped roasting chamber instead of cylindrical drum. These models became quite common in Europe over the 18th century and could be seen accompanying ambulant coffee street vendors using mobile versions of these spherical roasters. Though originally used for coffee, the drum roaster technology was adapted to suit any bean or nut that was desired in its roasted form.

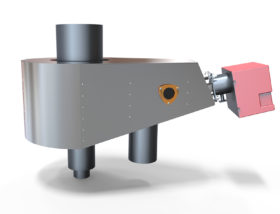

Since their inception, it was clear to Coffee-Tech Engineering that the secret to the perfect roasting machine is in the thermodynamic characteristics of the roasting vessel itself. Heat distribution and heat transformation between the vessel and the beans is more important than any other characteristic of the roasting process. From cocoa beans to cocoa nibs, barley, and other grains for the beer and spirits industry, Coffee-Tech Engineering has been asked to produce dedicated machines for all kinds of granulates, in all forms.. They have built more than a dozen different versions of their machines, all uniquely engineered for different purposes.

Among their clientele you can find large scale producers with well known products, enjoyed by the masses, and distributed globally. Working alongside such large and knowledgeable companies has granted the ability to evaluate performance in well-equipped laboratories. This opportunity, with well documented research has contributed a great deal to Coffee-Tech Engineering’s manufacturing process. The enduring pursuit for a perfect thermal dialog between substance and apparatus, started with the addition of the stirring stick to the roasting pan back there in the dessert, a long time ago. Continuing today with the addition of thermodynamic drums, roasting organic beans to perfection will always be a never ending challenge.

When Coffee-Tech Engineering created the FZ94 Pro-Lab Roaster it was meant to serve as a research and development tool for the entire food industry, not limited to coffee. The FZ94 was engineered to be fully customizable with any type of drum and any features you can imagine. This makes it the perfect small batch roaster to facilitate the artisan chocolate maker in roasting their own raw cocoa during the chocolate making process. Keeping the external dimensions and appeal of their original form, the cocoa roasters are not just modified coffee roasters, they have an entirely dedicated internal design purposed specifically for cocoa beans. This is what you would expect from a manufacturer that offers several different drum options only for coffee. All their modified features are hidden and embedded with-in the machine, external features can not improve the quality of a product greater than its own organic design. Any development that has been successful with the FZ94 can be implemented in their Ghibli line of commercial roasters as well.

Coffee and Cocoa are both roasted with varying methods in today’s marketplace. Whether it is using a wood fire, a gas flame, or electric heating elements, the process of rotation and equal heat distribution over a period of time remains the formula. Years after Coffee-Tech Engineering created their first cocoa roaster, they are still active within the cocoa community and have developed a reputation for manufacturing high quality artisan and commercial cocoa roasting machines. Manufacturing the FZ94, Silon ZR7, and the complete Ghibli line with researched and established cocoa roasting modifications to their roasters, Coffee-Tech Engineering has given chocolate makers the ability to roast cocoa with the same flexibility, accuracy, and perfection as our beloved coffee.

Consideration to Ram Evgi for his assistance

Chris Nance / Moshav Mazliach / 15.3.2020