The Ghibli R30 Commercial Coffee Roaster is an advanced roasting machine that allows perfect control over the roasting process, in order to meet the desired results and cup profiles. The Ghibli R30 enables roast masters to pre-define their desired calibration preferences.

Durability

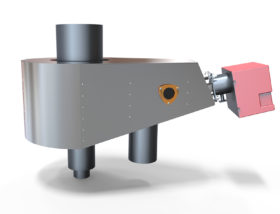

Our Ghibli R30 is a heavy duty machine with robust features under the hood. It offers a fully-closed fairing protected by its insulated, and covered-drum housing. The Ghilbli R30 comes complete with smart-thermal sensors and noise-reduction components.

New generation installation choices

The ergonomic design is ambidextrous for both right and left-hand users. This left/right selection option enables users to install and position Ghibli R30 in any desired location, regardless of the existing infrastructure on site.

Clean, Green, & Safe

The Ghibli R30 is designed to achieve the highest roasting efficiency, to minimize pollution, and reduce gas consumption. The R30 brings our continued research in thermodynamics, airflow routing, precision gas burners, and high-efficiency combustion chambers, to reality.

Quality

Making a huge step forward in quality roasting, the Ghibli R30 delivers superb results, free from defects, even with the most stubborn beans. It shows a wonderful smooth ride over the entire batch, and is also suited for rapid roasting batches. It is also perfectly suited to roast smaller quantities, less than a full batch.

Precision Design

To deliver unmatched power and precision, the Ghibli R30 is based on advanced product design software, extensive lab research, and rigorous testing methodologies. The result is a meticulously designed roaster, which optimizes the entire scope of elements that produce a superior roasting process.

Advanced set of features:

• Advanced thermodynamic characterization.

• Smart Vortex drum, allowing 90% less air to alter the heating characteristics.

• Fully modulated burner, providing precise control with 100% burner power resolution.

• Option for two gas burners.

• Dual positioning option for the burner relative to the drum.

• Precision drum housing, to ensure the drum always spins “in line”, with a sturdy design.

• In-drum fluidizing paddles, designed to perfectly stir the beans.

• A high capacity, high pressure cooling blower provides a substantially shorter batch cooling time.

• LED-illuminated magnifying glass, for better trier sample viewing

• Enhanced visibility with three tempered glass lenses encircle the roaster. These lenses provide easy viewing into the combustion chamber, green hopper window, and into the drum to view your beans while roasting.

• A collection bucket is supplied for the roasted beans, made by food-grade stainless steel, wheeled, and elegantly styled to complement this lavishly-designed machine. Replacing any unfitted plastic containers that function as elaborate collectors.

Perfect Heat Dispersion

As part of the entire Ghibli line, the R30 is designed with a closed ceramic combustion chamber surrounding the drum, ensuring heat distribution remains uniform at all times. Secondary air is allowed to enter by measure, and only through specific ducts positioned at the most crucial points. The heat is exchanged with the cold air on its way to the drum, with maximized efficiency.

Clean, Green, Safe, and Efficient Heating System

The new Vortex drum design dramatically reduces the required intake of the secondary cold air flow. This directly impacts the amount of gas for burning, so that much less is needed to keep the process at optimized temperature ranges. Less gas means lower running cost, fewer impurities and polluting fumes, and minimized energy for smoke treatment with less air and less combustion. Coffee-Tech’s entire Ghibli line features a highly efficient pre-mix, low NOx gas burner. The Ghibli R30 roaster comes equipped with one or two fully modulated burners. It provides a wide range of settings that easily maintain a constant heat. The roaster’s clean heat source provides maximum gas-burning efficiency, with minimum levels of carbon monoxide emissions. Safe for the operator, roastery employees, and the coffee itself. The Ghibli R30 is highly cost effective and stable, featuring many parameters for control and calibration as described in detail in our user manual. Each machine is tested and calibrated using a combustion gas analyzer, for optimal calibration.

User and Ambient Safety

Coffee-Tech Engineering’s entire Ghibli line is constructed with a closed-sealed ceramic combustion chamber. The combustion chamber is the drum housing itself, which is under negative pressure throughout the roasting process. Sucking the secondary air through specific ducts, it is the only place into which air can penetrate. Our advanced design ensures the roaster’s surrounding is kept completely pollutant free, with zero gas or odor discharged to the immediate environment. Coffee-Tech Engineering machines are designed for a superior roasting experience, with a superior coffee flavor, while ensuring top safety measures.

Safety

• Coffee-Tech Engineering roasters, the Ghibli R30 among them, are featured with an in-drum fire extinguishing faucet that is connected to a live water line.

• The R30 is equipped with a manual drum evacuation crank. In the case of a fire, users can perform the procedure single-handedly, as the drum door automatically remains open based on our safety design and advanced mechanisms.

• The outer stainless steel wall is shielded by the machines fairing, to ensure no heat is reflected back onto the user or into their surroundings.

Feature-Rich Offering

• Drum door is smoothly operated on oil-free bearings, and has an intricate dead-lock closing mechanism instead of those nasty metal weights.

• Drum gap is easily set by a micrometric regulation hub, even while the machine is in mid-cycle. Trust us, our experience has shown that no one thinks alignment is needed without having it, so we added this highly expensive mechanism to cut support time for the benefit of our users.

• The roaster’s main self-aligning bearing hub is sealed, to avoid grease leaking onto the cooling pan.

• The roaster has a smart drum opening and paddle geometry for fast drum evacuation.

Roast Profile

Ghibli R30 is equipped with a touch-screen panel and built-in roasting profiler, exclusively developed by Coffee-Tech Engineering. Users can pre-set and control the roasting process, for either manual or automated mode. It can also integrate into roast data logging applications and software, using an external USB cable. This Profiler enables any user to pre-define and program their personal roast profiles. By recording the desired heating curves, any roast profile can be applied time and again, with pinpoint accuracy.

• Ergonomically designed for simple operation and easy maintenance. The control panel features an emergency stop switch, a USB port for computer connection, and an accessory operating platform that includes optional features such as de-stoner and pneumatic loader with individual frequency inverters. Any other optional feature can be added, hassle-free.

• The profiler analyzes the internal temperature at three distinct locations, simultaneously managing the fully modulating burner. In addition, the software also controls the drum speed and airflow within the drum, allowing complete control over the entire process.

Robust Yet Simple Chaff Evacuation System (Optional)

Ghibli R30 can come with an automatic, heavy-duty chaff evacuation system. It continuously empties the chaff into an external bucket, and is designed to ensure no accumulation falls inside the cyclone. During operation, all that remains is to simply dump the contents of the bucket, at any time. To clear the chaff, there is no need to stop the machine or rush over to it especially at any point during your roast, since the chaff has already exited the machine.

Chaff Compacting Device (Optional)

For the Ghibli line, a compacting device can be ordered to complete the chaff evacuation system. It packs the chaff into small capsules that can be put away for later reuse in heating or for agricultural purposes.

Cooling Group

The Ghibli R30 is equipped with a stainless steel cooling group, which has a large stainless steel screen mesh that remains clean and residue-free for life.

Here are some of its benefits

No cleaning is required, as it operates with a Teflon agitation blade and a dedicated high-capacity cooling blower. The cooling group also features two cleaning doors for easy access.

Next-Generation Vortex Roasting Drum

The Ghibli R30 blasts an airstream in spiral motion into the drum and through the coffee bean mass, requiring a smaller amount of air to enter the roaster for a full effect. The longer spiral path across the drum and through the coffee bed is unlike the olden traditional roaster mechanisms, which had a perforated back plate allowing huge amounts of air into the drum in a short, straight path. With our Ghibli line, the beans are not stripped from their natural coffee aromas or taste. The energy of the airflow is also used to maintain the heat next to the exhaust. This innovative approach ensures a unique added-value for cost-effectiveness, energy optimization, and enhanced flavor. Lab tests have already shown a huge improvement in the coffee’s solids content and density, with amazing improvements in gas consumption, roasting time, and fume emissions.