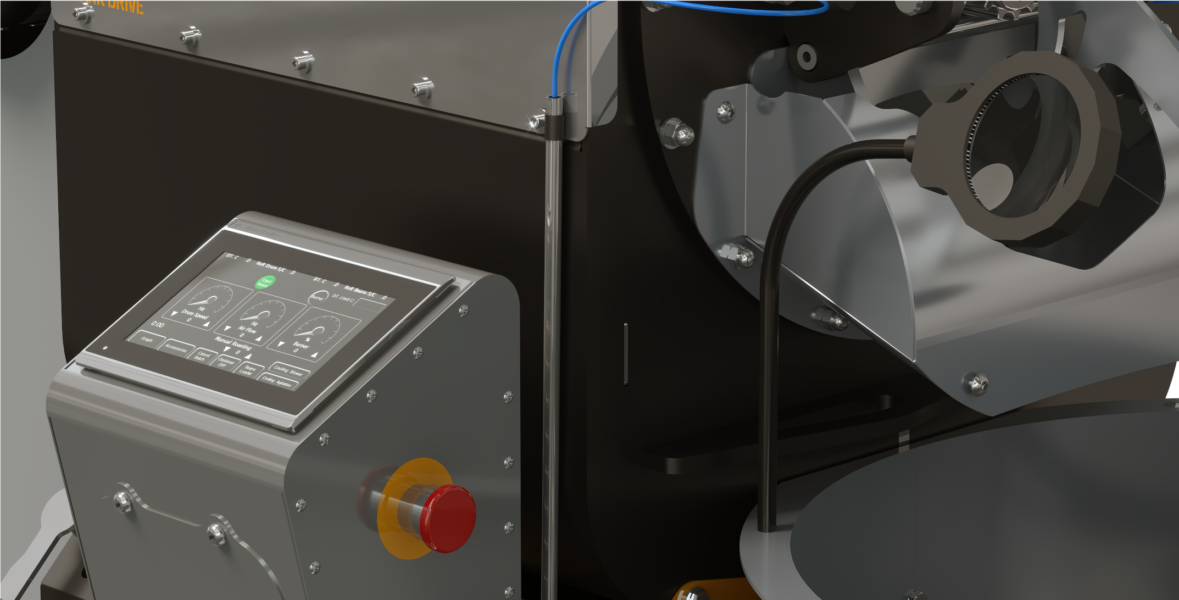

The Ghibli R15 commercial cocoa roaster has a dedicated internal design specialized to meet the quality needs for industrial cocoa roasting in medium volume production facilities. The Ghibli R15 commercial cocoa roaster features full professional profiles and heavy-duty design for quality roasting and reliable operation.

The Ghibli R15 commercial cocoa roaster roasts continuously while cooling is done outside the drum, allowing you to roast more Kg per hour. The Ghibli R15’s construction excels in its high craftsmanship thanks to CAD design and high production standards.

The Ghibli R15 commercial cocoa roaster was designed to provide the latest technology, for those who really understand and appreciate quality, and for those who deserve the best. The Ghibli R15 is much more than a rotating “barrel on flames”. For us, at Coffee-Tech Engineering, perfection and advancing technology is our goal.

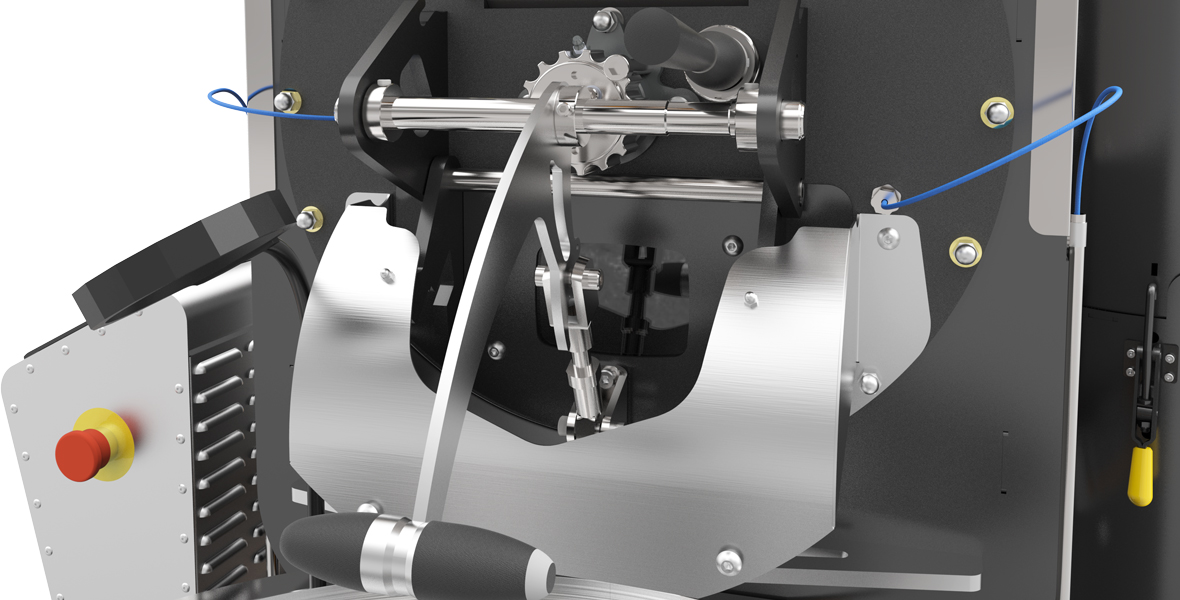

The Ghibli R15 is a product that was designed using the most advanced product design software from start to finish. This helped us optimize parameters such as: advanced thermodynamic characterization; optimal heat distribution; robust accurate drum housing which keeps the drum spinning “in line” for life; drum proportion for an optimal ratio between heat conduction and heat convection; in drum agitation design for perfect beans fluidizing; greater conduction between metal and beans; chaff separation and immediate bean evacuation from the drum to the cooling group in order to bring the roasting process to an immediate stop; perfect heat dispersion thanks to a well-studied ceramic combustion chamber optimally located against the drum, spreading heat equally around the drum.

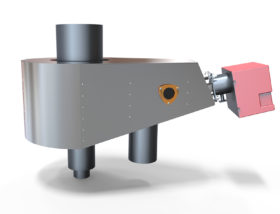

Coffee-Tech’s entire Ghibli line is equipped with the most efficient turbo gas burner. It is a clean heating source, providing maximum efficiency in gas burning and minimal emission of Carbon Monoxide. It is safe, economical and stable, with many unique parameters to control and calibrate as described in detail in our user manual.